Pipe Markers & ID Labels

In order to ensure the health and safety of your workers, valves and pipes need labels that provide essential information. The ANSI ASME A13.1 general pipe marking standards provide a common approach to labelling different pipes. Our pipe markers and valve tags follow the recommended colour guideline for pipes used for various purposes.

Read the Pipe Marking Guide >>

Lucas Products and Services has been in the industrial appliances labelling sector for over 20 years. We offer a variety of pipe markers that correspond to the health and safety regulations in your industry. Our customer care team have the expertise and are available online to guide you through the required custom pipe labelling specifications. You only need to provide the size of pipes, condition of pipes, content of pipes and the workplace environment and then leave the task of making a correctly coloured and marked label to us.

Categories of Custom Pipe Markers

- Snap- Around Labels (Wrap-Around)

- Self-Adhesive Labels

Snap-Around Labels

Our snap-around markers are suitable for pipes that are difficult to mark since you just wrap around the pipe. The pipe markers are usable in dirty, greasy, oily and rough pipes and require no preparation before installation. You can use these labels in pipes with diameters that are larger than 6”. These markers serve as safety tags in electrical and fire applications.

Self-Adhesive Labels

These are easy-to-peel adhesive labels which you tape to clean and dry surfaces. They are compliant with the ANSI ASME A13.1 standards when used with arrow directions. We use grade vinyl to ensure that your pipe markers last for about 5 years when used in the recommended temperatures. This type of pipe marking is suitable for acids & bases markers, air & ducts, maintenance & operation, water, direction markers, IIAR Ammonia markers, fire systems and gases.

Pipe Marking/ ANSI ASME A13.1 Standards

Labelling of pipes depends on the size, condition, content and workplace environment of the pipes. The ANSI ASME A13.1 requirements standards give guidelines on the colour codes. Industries must comply as a way of warning workers of a potential hazard. Pipes containing fire-quenching fluids should be labelled in red with white text. Flammable fluids use yellow labels with black texts. Gases in either gas or liquid phase also use yellow. Combustible fluids have brown labels with white text. Toxic and corrosive fluids ought to have orange labels with black text. Portable, cooling, boiler feed and other water pipes require a green coloured label in white text, while compressed air pipes use blue labels with white text.

In order to offer reasonable visibility to plant personnel from the normal point of approach, there are specified label dimensions of the letter height, length of colour field and the outside diameter of pipe. Pipe markers should be placed adjacent to all valves and flanges, at both sides of the floor, adjacent to change in direction and every 25 to 50 ft intervals on straight runs.

Lucas Products Pipe Markers

We offer high-quality vinyl labels in the various categories:

- Peel & Stick Adhesive Pipe Markers

- Roll-Form Pipe Markers

- Snap-Around Pipe Markers

- Pipe Identification Tape

Why Choose Lucas Pipe Markers

The pipe marking follows ANSI/ASME A13.1 and British Standards BS 17:10 and can also use custom colours in line with on-site project requirements. We have silver markers for steam pipes, purple markers for acid and base pipes, orange markers for electrical pipes and yellow markers for gas pipes.

We also print International Safety Symbols onto pipe markers in line with globally recognised symbols of communicating a potential hazard. Lucas Products also print GHS symbols on pipe markers adhering to the standard classification and labelling of chemicals. The various sizes of each pipe marker type are available online on our site.

Contact us via phone number for a free quotation or email us an enquiry, and we will provide you with pipe marking solutions.

-

Custom Snap Pipe Markers Pack (No Symbols)

Snappy in many ways!

Snap To Pipe Markers just wrap around the pipe, no adhesive. Quick and easy to apply, no preparing pipework. (Pack of 5)

Simply go to the Product Customisation Tab below and enter/upload your custom wording before you Add to Cart.

Call for PriceCustom Snap Pipe Markers Pack (No Symbols)

Call for Price -

Directional Pipe Identification Tape – 8 Colours Available

Custom Printed Pipe Identification Tape with or without arrows or text legends. Each roll of pipe tape is 25 Metre in length with a width of 50mm wide including single colour print.

Call for PriceDirectional Pipe Identification Tape – 8 Colours Available

Call for Price -

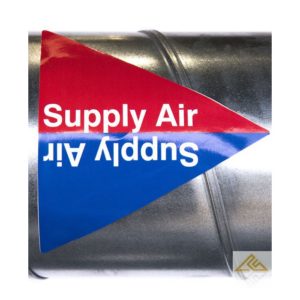

Duct Pipe ID Labels Pack of 10

Marking your ductwork – ventilation, heating and HVAC.

Material: Vinyl

Shape: Triangle

Diameter: 150mm x 150mm x 150mm

Fixing: Self-adhesive backing

Pack Quantity: 10See PRODUCT CUSTOMISATION tab below

Call for Price -

High Performance Custom Snap Pipe Markers Pack (with Symbols)

Snappy in many ways!

Snap To Pipe Markers with symbols just wrap around the pipe, no adhesive. Quick and easy to apply, no preparing pipework. (Pack of 5)

Simply go to the Product Customisation Tab below and enter/upload your custom wording and symbol information before you Add to Cart.

Call for Price -

Pipe Marker 10 Pack – Acids & Alkalis Coloured Coded Violet

Self-Adhesive Pipe Markers

PEEL & STICK PIPE MARKER RANGE

Description: Violet Arrow Ended Pipe Markers with white text (Pack of 10). For directional flow, leave the arrow indicating the direction, and cut off the arrow from the other side.

Simply go to the Product Customisation Tab below and enter/upload your custom wording data before you Add to Cart.

Call for PricePipe Marker 10 Pack – Acids & Alkalis Coloured Coded Violet

Call for Price -

Pipe Marker 10 Pack – Air Coloured Coded Blue

Self-Adhesive Pipe Markers

PEEL & STICK PIPE MARKER RANGE

Description: Blue Arrow Ended Pipe Markers with white text (Pack of 10). For directional flow, leave the arrow indicating the direction, and cut off the arrow from the other side.Simply go to the Product Customisation Tab below and enter/upload your custom wording data before you Add to Cart.

Call for PricePipe Marker 10 Pack – Air Coloured Coded Blue

Call for Price -

Pipe Marker 10 Pack – Electrical & Ventilation Coloured Coded Orange

Self-Adhesive Pipe Markers

PEEL & STICK PIPE MARKER RANGE

Description: Orange Arrow Ended Pipe Markers with black text (Pack of 10). For directional flow, leave the arrow indicating the direction, and cut off the arrow from the other side.

Simply go to the Product Customisation Tab below and enter/upload your custom wording data before you Add to Cart.

Call for Price -

Pipe Marker 10 Pack – Fire Fighting Coloured Coded Red

Self-Adhesive Pipe Markers

PEEL & STICK PIPE MARKER RANGE

Description: Red Arrow Ended Pipe Markers with White text (Pack of 10). For directional flow, leave the arrow indicating the direction, and cut off the arrow from the other side.

Simply go to the Product Customisation Tab below and enter/upload your custom wording data before you Add to Cart.

Call for Price -

Pipe Marker 10 Pack – Gases Colour Coded Yellow

Self-Adhesive Pipe Markers

PEEL & STICK PIPE MARKER RANGE

Description: Yellow Arrow Ended Pipe Markers (Pack of 10) with black text. For directional flow, leave the arrow indicating the direction, and cut off the arrow from the other side.

Simply go to the Product Customisation Tab below and enter/upload your custom wording data before you Add to Cart.

Call for PricePipe Marker 10 Pack – Gases Colour Coded Yellow

Call for Price -

Pipe Marker 10 Pack – Steam Coloured Coded Grey

Self-Adhesive Pipe Markers

PEEL & STICK PIPE MARKER RANGE

Description: Grey Arrow Ended Pipe Markers with black text (Pack of 10). For directional flow, leave the arrow indicating the direction, and cut off the arrow from the other side.

Simply go to the Product Customisation Tab below and enter/upload your custom wording data before you Add to Cart.

Call for PricePipe Marker 10 Pack – Steam Coloured Coded Grey

Call for Price -

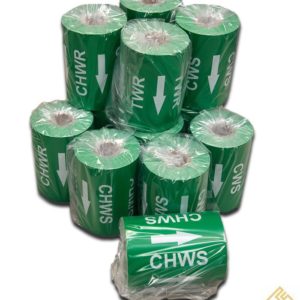

Pipe Marker 10 Pack – Water Coloured Coded Green

Self-Adhesive Pipe Markers

PEEL & STICK PIPE MARKER RANGE

Description: Green Arrow Ended Pipe Markers with white text (Pack of 10). For directional flow, leave the arrow indicating the direction, and cut off the arrow from the other side.Simply go to the Product Customisation Tab below and enter/upload your custom wording data before you Add to Cart.

Call for PricePipe Marker 10 Pack – Water Coloured Coded Green

Call for Price -

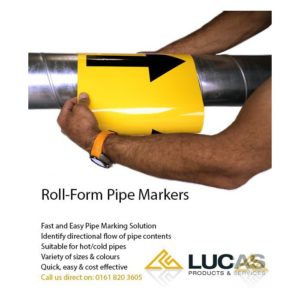

Roll-Form Pipe Markers

Lucas Roll-Form Pipe Markers wrap around pipe markers with adhesive. Available in 10m rolls in length, and either 50mm or 100mm wide.

CUSTOMISE YOUR ROLL-FORM PIPE MARKER. Add your TEXT/LEGEND below & SAVE before ADD TO CART.

Call for PriceRoll-Form Pipe Markers

Call for Price